Factory price PP/PS sheet extrusion line Thermoforming Sheet

Production Line plastic machine

Main Technical Parameters

| Suitable Material | APET,PETG,CPET |

| Width | 650-1550mm |

| Thickness | 0.10-1.5mm |

| Capacity | 450-1200kg/h |

| Extruder | Twin screw extruder |

Product Features

Intelligent and Humanized Design: The production line is designed with intelligence and

humanization, making it easy to operate while ensuring high output

and low energy consumption.

Model and Application Range: The equipment model is CHD L=600mm-1500mm, with a production

capacity of 100kg/h- 1200kg/h, suitable for food packaging,

electronic prorduct packaging, and stationery fields, among others.

Versatility: According to different product requirements, the PP/PS sheet

extrusion line can produce single-layer, double- layer, and

multi-layer co-extruded sheet products

Technical Details

"One-Key Acceleration" Feature: The equipment has a unique "one-key acceleration" feature that

allows for low-speed adjustment and high- speed production,

reducing material waste during the machine setup process.

Control System: An intelligent advanced control system is used to ensure stable

equipment operation and reduce information transmission errors.

Rolling Control: The rolling part uses servo control, which is precise and safe

High-Quality Components: The entire set is equipped with first-tier international brand -

Siemens frequency conversion servo control, improving the

efficiency, precision, and stability of the equipment.

After-Sales Service

The company provides comprehensive services from equipment

installation and debugging to the production of high-quality

products, and promises lifetime technical support.

Core Components

Feeding form |

Screw-type |

Feeding capacity | 1000kg/h |

Control mode |

Variable frequency motor speed control |

Converter |

SIEMENS Siemens 3KW, using Ethernet control technology |

Band |

Tuya |

Structure form |

Full-network double-column screen changer with hydraulic station |

Heating zone |

Two zones |

Heating power |

Approx.10kw |

Brand |

JCTIMEC |

Rated speed metering | 8-60r (revolutions)转/min 8-60r rpm |

Model number | E90,(371CC) |

Gearbox and motor power |

SIEMENS Siemens reducer, 7KW servo motor

|

Variable conversion control |

Siemens, using Ethernet control technology |

Brand |

JingCheng |

Structure form |

Hanger runner |

Width of final product | 860mm |

Thickness of final product | 0.2-1.0mm |

Effective width of mold | 1100mm - 外堵单面100 Single-sided outer plug

|

Heating zone | 8zones |

Heating power | 30KW |

Roller size |

lower roller diameter 400mm, middle and upper roller diameter 600mm |

Roller width | 1200mm |

Roller materials |

alloy steel |

Roller surface roughness |

mirror finish |

Hardness | ≥HRC60-62 |

Chrome layer thickness | 0.08mm-0.12mm |

Drive motor |

SIEMENS Siemens servo motor, 3 sets*7KW |

Linear velocity

| 6-60m |

Reduction gear |

SIEMENS Siemens Gearbox, 3 sets |

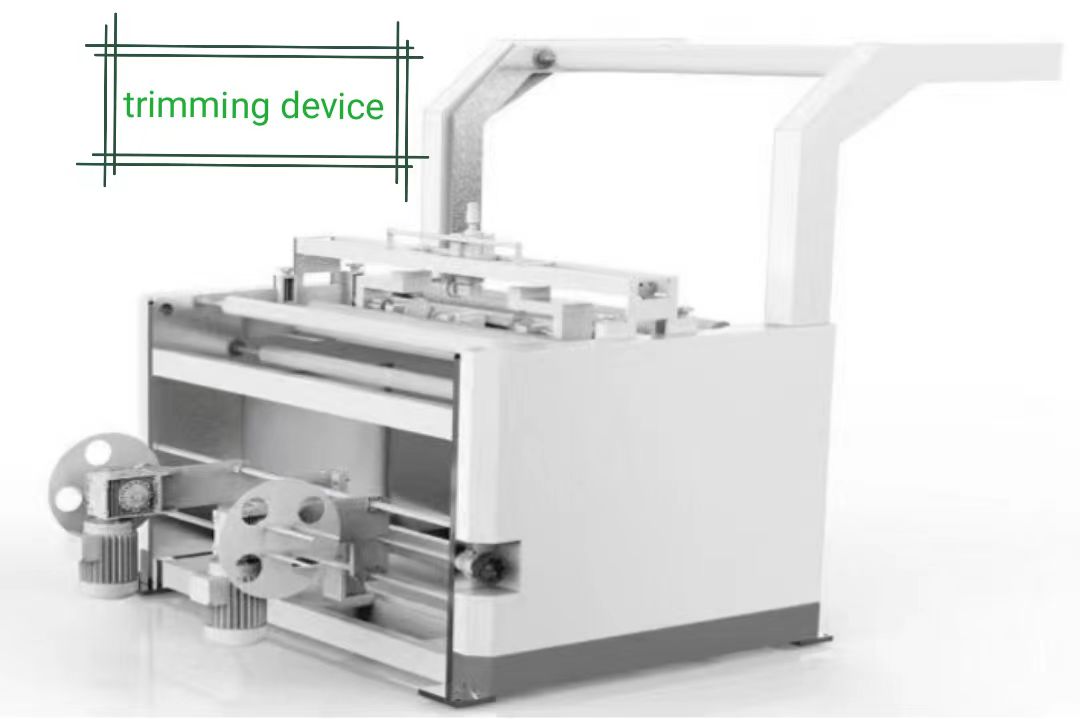

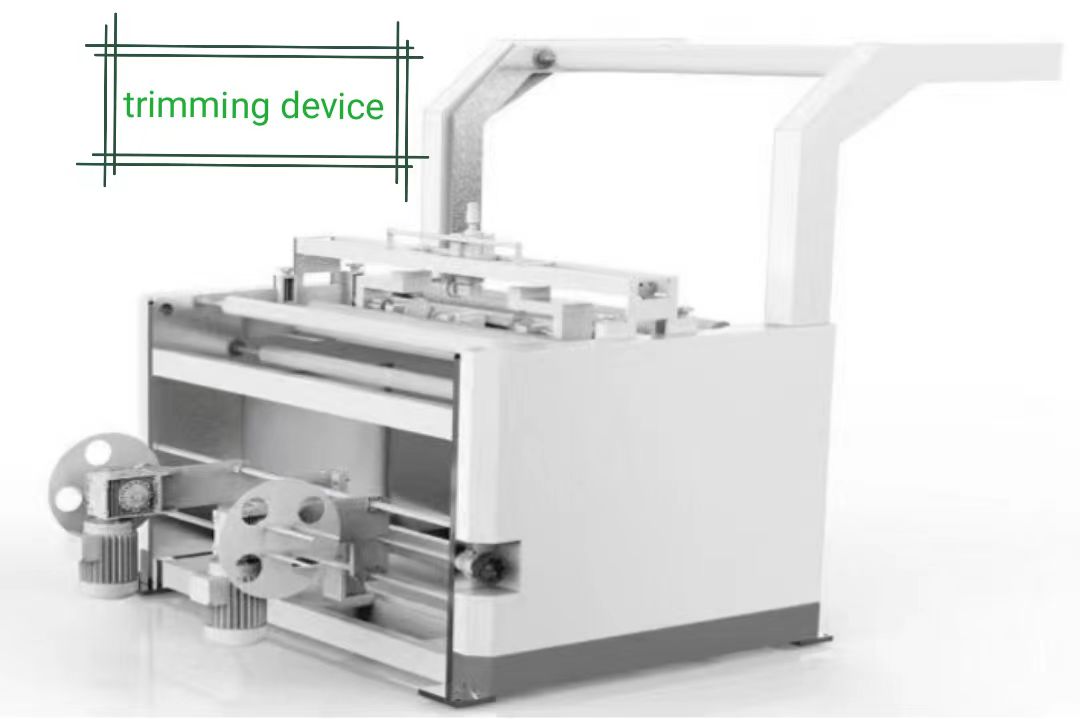

Edge triming assembly |

1 group, 3 knives, 1 group of left, middle and right, adjustable

distance |

Cutter form |

rotary cutter |

Ferrules winding |

a set |

Ferrules winding drive |

0.4KW servo-motor control |

Form structure |

Flip-type double-station winder |

Air-expanded shaft |

3 inch, 6 inch general, both ends of the installation of mechanical

clutch, convenient disassembly of gas expansion shaft |

Maximum winding diameter | 1200mm |

Drive the motor | 3.5KW A Siemens servo-motor |

Unwinding method |

Manual |

Winding method |

Automatic |