Core components

Feeding form |

Screw-type |

Feeding capacity | 1000kg/h |

Control mode |

Variable frequency motor speed control |

Converter |

SIEMENS Siemens 3KW, using Ethernet control technology |

Band |

Tuya |

Structure form |

Full-network double-column screen changer with hydraulic station |

Heating zone |

Two zones |

Heating power |

Approx.10kw |

Brand |

JCTIMES |

Rated speed metering | 8-60r (revolutions)转/min 8-60r rpm |

Model number | E90,(371CC) |

Gearbox and motor power |

SIEMENS Siemens reducer, 7KW servo motor

|

Variable conversion control |

Siemens, using Ethernet control technology |

Brand | JCTimes |

Structure form |

Hanger runner |

Width of final product | 860mm |

Thickness of final product | 0.2-1.0mm |

Effective width of mold |

Single-sided outer plug

|

Heating zone | 8zones |

Heating power | 约30KW |

Die head material | 5CrNiMo |

Mold cavity processing |

Surface chrome-plated and polished, polished chrome layer thickness

greater than 0.06mm, surface finish Ra ≥ 12 |

Roller size |

lower roller diameter 400mm, middle and upper roller diameter 600mm |

Roller width | 1200mm |

Roller materials |

alloy steel |

Roller surface roughness |

mirror finish |

Hardness | ≥HRC60-62 |

Chrome layer thickness | 0.08mm-0.12mm |

Drive motor |

SIEMENS Siemens servo motor, 3 sets*7KW |

Linear velocity | 6-60m |

Reduction gear |

SIEMENS Siemens Gearbox, 3 sets |

| Form |

L-type |

Forward and backward movement power | 0.75KW |

Front and rear lifting power | 0.9KW |

roller gap adjustment |

Adopting hydraulic cylinder to adjust the distance, worm gear

elevator micro-adjustment limit, with mechanical insurance, with

micro-adjustment and percentage meter device, with hydraulic

station, the highest pressure 15Mpa, with self-locking pressure

preservation function |

| three-roller bearing | NSK Nippon Seiko Kabushiki Kaisha) |

| water intake structure |

Left inlet and right outlet water mode |

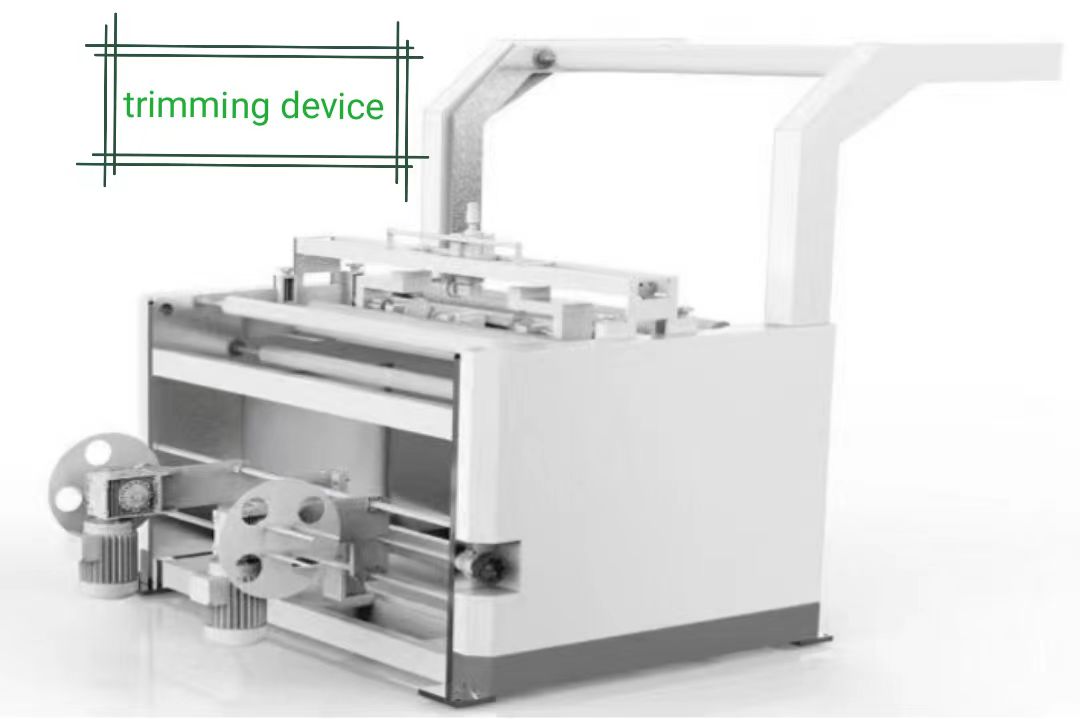

Edge triming assembly |

1 group, 3 knives, 1 group of left, middle and right, adjustable

distance |

Cutter form |

rotary cutter |

Ferrules winding |

a set |

Ferrules winding drive |

0.4KW servo-motor control |

Control system | PLC |

| CPU | SIEMENS S7-1500 |

| HMI | SIEMENS 12 inches |

Inverters | SIEMENS |

miniature Circuit Breakers | SIEMENS |

Small relay |

Schneider |

Solid state relay |

Swiss Galle |

Size | Ф200mm*1200mm |

Haul-off roller |

Upper rubber rollers and lower steel rods, rubber rollers cover

layer thickness 20mm, nitrile rubber, surface Shore hardness 65-70° |

Drive motors |

SIEMENS servo motor, 5KW |

Roll cylinder opening and closing |

Cylinder adjustment |

Wait controllers |

Using Ethernet technology control |

Form structure |

Flip-type double-station winder |

Air-expanded shaft |

3 inch, 6 inch general, both ends of the installation of mechanical

clutch, convenient disassembly of gas expansion shaft |

Maximum winding diameter | 1200mm |

Drive the motor |

A Siemens servo-motor |

Unwinding method |

Manual |

Winding method |

Automatic |

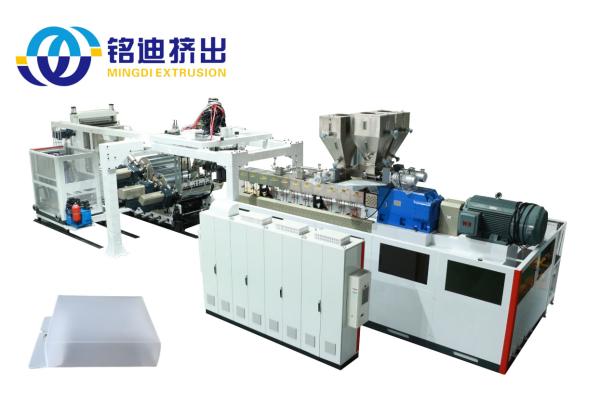

Production characteristics

Multi-layer composite technology: to achieve the effective composite of multi-layer fabrics,

to produce sheets with excellent properties, such as high barrier,

heat preservation, UV resistance, etc.

Precise control system: Equipped with Siemens PLC automatic control system to ensure

accurate control and efficient operation of the production process.

High productivity: Single screw extruder design, high output, fast production speed.

Quality after-sales service: Provide comprehensive installation, commissioning,

training and technical support to ensure customers worry-free use.

PET/PLA/PP/PS Sheet

Widely used in :degradegable lunch boxes,ordinary lunch

boxes,electronic product packaging,food packaging,printing

sheets,seeding tray sheets,etc.